全自動丁基膠涂布機操作注意事項:細節(jié)決定品質(zhì)與效率

時間:2025-05-27 來源:http://www.ttkjhz.net/ 發(fā)布人:昌盛機械

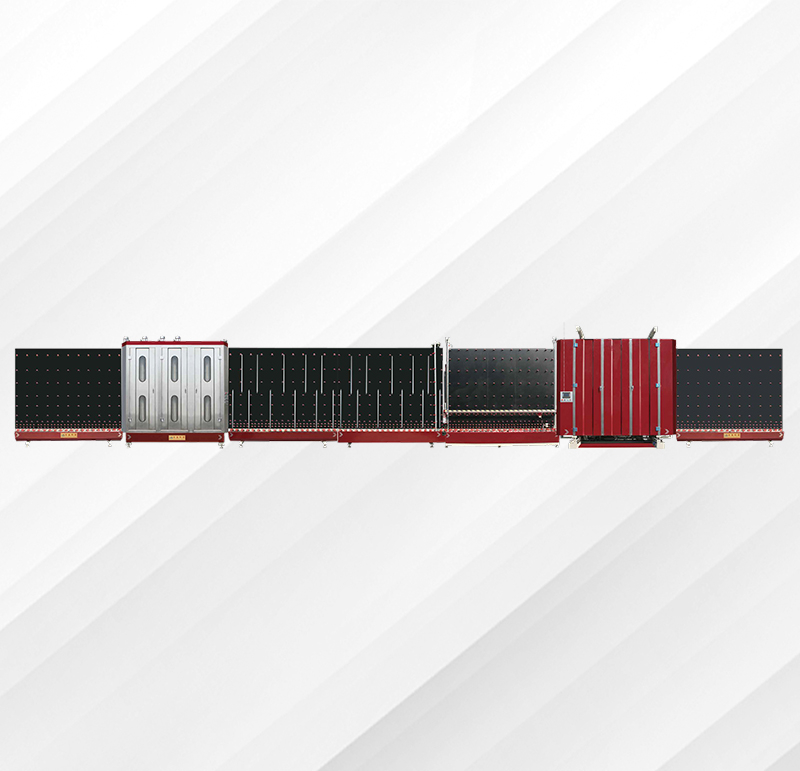

在現(xiàn)代化工業(yè)生產(chǎn)中,全自動丁基膠涂布機以其高效、精準的涂布性能,成為中空玻璃、光伏組件等制品生產(chǎn)線上不可或缺的關(guān)鍵設(shè)備。作為保障產(chǎn)品密封性與耐久性的“隱形工匠”,其操作規(guī)范直接關(guān)系到產(chǎn)品質(zhì)量與生產(chǎn)安全。本文將從設(shè)備啟用到日常維護,為您詳細解讀全自動丁基膠涂布機的安全操作要點。

In modern industrial production, the fully automatic butyl rubber coating machine has become an indispensable key equipment on the production line of insulating glass, photovoltaic modules and other products due to its efficient and precise coating performance. As the "invisible craftsman" who ensures the sealing and durability of products, their operating standards are directly related to product quality and production safety. This article will provide a detailed explanation of the safety operation points of the fully automatic butyl rubber coating machine from device activation to daily maintenance.

一、操作前:精心籌備,筑牢安全防線

1、 Before operation: Carefully prepare and build a secure defense line

設(shè)備狀態(tài)核查

Equipment status verification

每日開機前,需對設(shè)備進行全面“體檢”。檢查涂布頭、輸送帶、加熱模塊等核心部件是否完好,確認電氣線路無裸露、破損,緊急停止按鈕處于可觸發(fā)狀態(tài)。特別關(guān)注膠缸密封性能,避免丁基膠泄漏引發(fā)安全隱患。

Before starting up each day, a comprehensive "medical examination" of the equipment is required. Check whether the core components such as the coating head, conveyor belt, and heating module are intact, confirm that the electrical circuit is not exposed or damaged, and that the emergency stop button is in a triggered state. Pay special attention to the sealing performance of the rubber cylinder to avoid safety hazards caused by butyl rubber leakage.

材料適配性確認

Confirmation of Material Suitability

根據(jù)生產(chǎn)任務(wù)選擇適配的丁基膠型號,檢查膠料包裝完整性,避免使用過期或受潮膠料。同時,核對基材尺寸、厚度是否與設(shè)備參數(shù)匹配,防止因材料偏差導(dǎo)致涂布異常。

Select the appropriate butyl rubber model according to the production task, check the integrity of the rubber packaging, and avoid using expired or damp rubber. At the same time, check whether the size and thickness of the substrate match the equipment parameters to prevent coating abnormalities caused by material deviations.

安全防護升級

Security protection upgrade

操作人員必須佩戴防護眼鏡、防熱手套,長發(fā)需束入工作帽內(nèi)。設(shè)備周邊需保持1.5米以上安全通道,嚴禁堆放易燃物品。對于連續(xù)生產(chǎn)線,建議安裝防護罩或光柵隔離裝置,降低機械傷害風(fēng)險。

Operators must wear protective goggles and heat-resistant gloves, and long hair should be tied into a work cap. A safe passage of at least 1.5 meters must be maintained around the equipment, and it is strictly prohibited to stack flammable materials. For continuous production lines, it is recommended to install protective covers or grating isolation devices to reduce the risk of mechanical injury.

二、操作中:精準調(diào)控,守護工藝品質(zhì)

2、 In operation: precise control, safeguarding the quality of the craftsmanship

參數(shù)設(shè)置三步法

Three step method for parameter setting

預(yù)熱校準:提前30分鐘啟動加熱系統(tǒng),使用紅外測溫儀驗證涂布頭溫度是否達到工藝要求(通常120-160℃),溫差需控制在±5℃以內(nèi)。

Preheating calibration: Start the heating system 30 minutes in advance and use an infrared thermometer to verify whether the coating head temperature meets the process requirements (usually 120-160 ℃). The temperature difference should be controlled within ± 5 ℃.

速度匹配:根據(jù)膠料粘度與基材特性,通過人機界面設(shè)置輸送帶速度(建議范圍0.5-3m/min),確保膠條連續(xù)無斷點。

Speed matching: Based on the viscosity of the adhesive and the characteristics of the substrate, set the conveyor belt speed through the human-machine interface (recommended range 0.5-3m/min) to ensure that the adhesive strip is continuous without any breaks.

壓力微調(diào):采用漸進式調(diào)整法,每次調(diào)節(jié)涂布壓力不超過0.02MPa,觀察膠條寬度變化,直至達到0.8-1.2mm的理想狀態(tài)。

Pressure fine-tuning: Adopting a progressive adjustment method, the coating pressure should not exceed 0.02MPa each time, and the width of the adhesive strip should be observed until it reaches the ideal state of 0.8-1.2mm.

過程監(jiān)控雙保險

Dual insurance for process monitoring

視覺巡檢:每15分鐘檢查涂布效果,重點關(guān)注膠條均勻性、邊緣整齊度,使用塞尺測量膠層厚度(建議配備數(shù)字顯微鏡輔助檢測)。

Visual inspection: Check the coating effect every 15 minutes, focusing on the uniformity of the adhesive strip and the neatness of the edges. Use a feeler gauge to measure the thickness of the adhesive layer (it is recommended to equip a digital microscope for auxiliary detection).

數(shù)據(jù)追蹤:利用設(shè)備自帶的生產(chǎn)記錄功能,實時保存溫度、速度、壓力等參數(shù),形成可追溯的質(zhì)量檔案。

Data tracking: Utilizing the built-in production recording function of the device, real-time storage of temperature, speed, pressure and other parameters is achieved to form a traceable quality file.

異常處理四原則

Four principles of exception handling

膠條斷裂:立即停機檢查膠料溫度是否偏低,或輸送帶速度是否過快,清理涂布頭殘留膠塊。

Rubber strip breakage: Immediately stop the machine to check if the temperature of the rubber material is too low or if the conveyor belt speed is too fast, and clean the residual rubber blocks on the coating head.

膠料溢出:降低涂布壓力,檢查膠缸液位傳感器是否故障,及時補充膠料。

Rubber overflow: Reduce the coating pressure, check if the liquid level sensor of the rubber cylinder is faulty, and replenish the rubber in a timely manner.

基材偏移:調(diào)整導(dǎo)向輥位置,校準基材對中系統(tǒng),確保涂布位置精度≤±0.5mm。

Substrate offset: Adjust the position of the guide roller, calibrate the substrate alignment system, and ensure that the coating position accuracy is ≤± 0.5mm.

設(shè)備報警:切勿強制復(fù)位,需根據(jù)故障代碼查閱操作手冊,或聯(lián)系專業(yè)技術(shù)人員處理。

Equipment alarm: Do not force reset, refer to the operation manual based on the fault code, or contact professional technicians for handling.

三、操作后:科學(xué)維護,延長設(shè)備壽命

3、 After operation: scientific maintenance to extend equipment lifespan

深度清潔流程

Deep cleaning process

每日生產(chǎn)結(jié)束后,需執(zhí)行“三步清潔法”:

After the end of daily production, the "three-step cleaning method" needs to be executed:

殘膠清除:使用專用清洗劑擦拭涂布頭、膠缸,避免金屬工具刮擦導(dǎo)致部件損傷。

Residual glue removal: Use a specialized cleaning agent to wipe the coating head and glue cylinder to avoid component damage caused by metal tool scratching.

輸送帶保養(yǎng):用無塵布蘸取異丙醇擦拭輸送帶表面,去除膠漬與粉塵,涂抹食品級硅油防銹。

Conveyor belt maintenance: Use a dust-free cloth dipped in isopropanol to wipe the surface of the conveyor belt, remove glue stains and dust, and apply food grade silicone oil for rust prevention.

濾網(wǎng)更換:定期清理或更換膠路過濾網(wǎng)(建議每500小時更換一次),防止雜質(zhì)堵塞管路。

Filter replacement: Regularly clean or replace the rubber filter (recommended to replace every 500 hours) to prevent impurities from blocking the pipeline.

關(guān)鍵部件點檢

Key component inspection

每周對加熱模塊、伺服電機、傳感器進行專項檢查:

Conduct weekly special inspections on heating modules, servo motors, and sensors:

加熱模塊:使用紅外熱像儀檢測溫度分布均勻性,排查局部過熱點。

Heating module: Use an infrared thermal imager to detect temperature distribution uniformity and identify local hotspots.

伺服電機:檢查運行噪音與振動值,確認編碼器連接牢固。

Servo motor: Check the operating noise and vibration values, and confirm that the encoder is securely connected.

傳感器:用標準砝碼校驗張力傳感器精度,確保誤差≤±1%。

Sensor: Use standard weights to verify the accuracy of the tension sensor, ensuring an error of ≤± 1%.

潤滑保養(yǎng)規(guī)范

Lubrication and maintenance standards

按照設(shè)備潤滑圖表,每月對導(dǎo)軌、絲杠、軸承進行潤滑:

According to the equipment lubrication chart, lubricate the guide rails, screws, and bearings monthly:

導(dǎo)軌保養(yǎng):涂抹耐高溫潤滑脂,運行設(shè)備使?jié)櫥瑒┚鶆蚍植肌?/p>

Guide rail maintenance: Apply high-temperature resistant grease and run the equipment to evenly distribute the lubricant.

絲杠防護:安裝防塵罩,避免粉塵侵入影響傳動精度。

Screw protection: Install a dust cover to prevent dust from entering and affecting transmission accuracy.

軸承檢查:用手持式振動檢測儀監(jiān)測軸承狀態(tài),振動值超過7mm/s需立即更換。

Bearing inspection: Use a handheld vibration detector to monitor the condition of the bearing. If the vibration value exceeds 7mm/s, it should be replaced immediately.

全自動丁基膠涂布機作為精密制造設(shè)備,其操作規(guī)范直接決定著產(chǎn)品質(zhì)量與生產(chǎn)安全。從開機前的細致檢查,到過程中的精準調(diào)控,再到收工后的科學(xué)維護,每個環(huán)節(jié)都需以匠心精神對待。唯有如此,才能讓這臺“密封藝術(shù)大師”持續(xù)輸出高品質(zhì)產(chǎn)品,為現(xiàn)代工業(yè)生產(chǎn)保駕護航。

As a precision manufacturing equipment, the operation specifications of the fully automatic butyl rubber coating machine directly determine the product quality and production safety. From meticulous inspection before startup, precise control during the process, to scientific maintenance after completion, every step needs to be treated with ingenuity. Only in this way can this "master of sealing art" continue to produce high-quality products and safeguard modern industrial production.

本文由全自動丁基膠涂布機友情奉獻.更多有關(guān)的知識請點擊:http://www.ttkjhz.net我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.ttkjhz.net We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 全自動封膠線中中板壓與棍壓的區(qū)別 2025/11/15

- 中空玻璃加工設(shè)備?故障分析流程 2025/11/14

- 中空玻璃生產(chǎn)線:中空玻璃生產(chǎn)流程及所需要設(shè)備 2025/11/13

- 丁基膠涂布機液壓油的選擇指南 2025/10/31

- 玻璃涂布機設(shè)備操作流程 2025/10/30

- 雙組份打膠機比例怎么調(diào) 2025/10/29

- 全自動鋁條折彎機折彎角度偏差的解決方法 2025/10/29

- 中空玻璃丁基膠涂布機漏油怎么解決 2025/10/28

- 臥式丁基膠涂布機糾偏原理 2025/10/27

- 立式丁基膠涂布機故障維修 2025/10/25

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當前位置:

當前位置: