全自動封膠線使用注意事項:保障高效穩(wěn)定運行的關(guān)鍵要點

時間:2025-07-24 來源:http://www.ttkjhz.net/ 發(fā)布人:昌盛機械

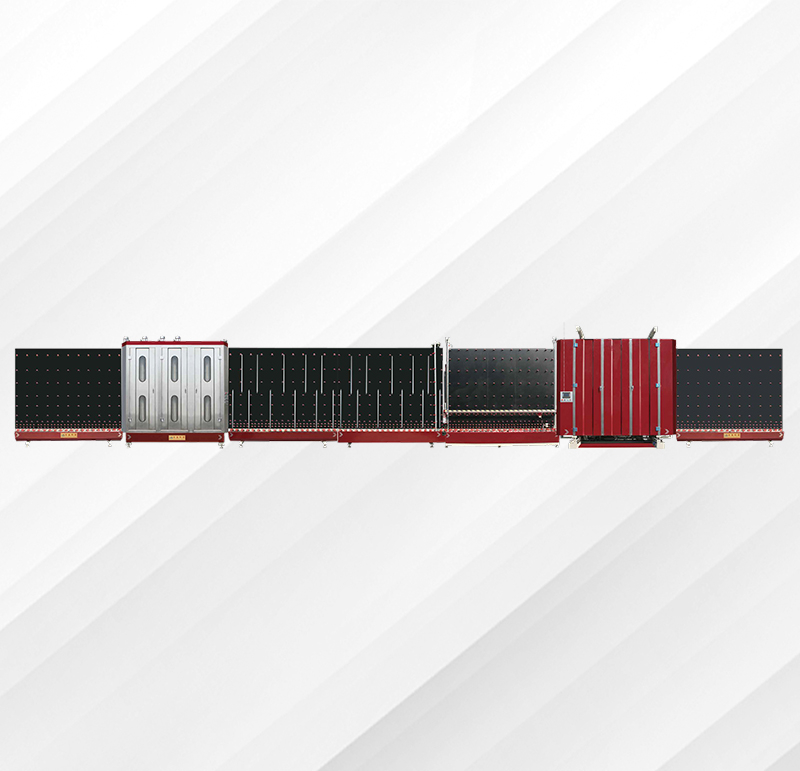

全自動封膠線作為實現(xiàn)密封膠均勻涂布的自動化設(shè)備,廣泛應(yīng)用于建材、汽車零部件、電子元件等領(lǐng)域的密封工序,其運行狀態(tài)直接影響產(chǎn)品密封性能(如防水、防塵、防漏)與生產(chǎn)效率。使用過程中需兼顧設(shè)備特性、膠料性能與操作規(guī)范,通過科學(xué)管理規(guī)避常見問題(如膠線斷膠、氣泡、尺寸偏差),確保封膠合格率穩(wěn)定在 99% 以上,同時延長設(shè)備使用壽命(通常可達 5-8 年)。

As an automated equipment for achieving uniform application of sealant, the fully automatic sealing line is widely used in sealing processes in the fields of building materials, automotive parts, electronic components, etc. Its operating status directly affects the sealing performance (such as waterproof, dustproof, leak proof) and production efficiency of the product. During use, it is necessary to consider the characteristics of the equipment, the performance of the rubber material, and the operating standards. Common problems such as broken rubber lines, bubbles, and dimensional deviations should be avoided through scientific management to ensure a stable sealing qualification rate of over 99%, while extending the service life of the equipment (usually up to 5-8 years).

設(shè)備啟動前的準(zhǔn)備工作是保障運行的基礎(chǔ),需覆蓋參數(shù)核查與狀態(tài)確認(rèn)。首先檢查膠料狀態(tài):密封膠需提前預(yù)熱至 25-35℃(粘度控制在 5000-15000mPas,根據(jù)膠種調(diào)整),避免因溫度過低導(dǎo)致流動性差(出現(xiàn)膠線斷續(xù))或過高導(dǎo)致膠料變質(zhì)(適用期縮短)。膠料桶需密封良好(防止空氣進入產(chǎn)生氣泡),并通過濾網(wǎng)(精度 50-100 目)過濾雜質(zhì)(雜質(zhì)會堵塞膠嘴,造成涂布不均)。其次校準(zhǔn)設(shè)備參數(shù):根據(jù)產(chǎn)品尺寸設(shè)定膠嘴移動速度(10-50mm/s)、膠量輸出(0.5-5ml/s)、膠線寬度(2-10mm),并通過試涂確認(rèn)膠線位置偏差(≤±0.5mm),必要時調(diào)整機械定位(如導(dǎo)軌平行度、膠嘴高度)。最后檢查輔助系統(tǒng):壓縮空氣壓力需穩(wěn)定在 0.4-0.6MPa(壓力波動≤±0.02MPa),否則會導(dǎo)致膠量忽大忽小;加熱裝置(如膠管加熱帶)需提前啟動,確保膠料在輸送過程中溫度恒定(偏差≤±2℃)。

The preparation work before equipment startup is the foundation for ensuring operation, which needs to cover parameter verification and status confirmation. Firstly, check the condition of the adhesive material: the sealant needs to be preheated to 25-35 ℃ in advance (viscosity controlled at 5000-15000mPas, adjusted according to the type of adhesive) to avoid poor fluidity (intermittent adhesive lines) caused by low temperature or deterioration of the adhesive material (shortened shelf life) caused by high temperature. The glue bucket needs to be well sealed (to prevent air from entering and generating bubbles), and impurities should be filtered through a filter (with an accuracy of 50-100 mesh) (impurities can clog the glue nozzle and cause uneven coating). Next, calibrate the equipment parameters: set the nozzle movement speed (10-50mm/s), adhesive output (0.5-5ml/s), and adhesive line width (2-10mm) according to the product size, and confirm the adhesive line position deviation (≤± 0.5mm) through trial coating. If necessary, adjust the mechanical positioning (such as rail parallelism and nozzle height). Finally, check the auxiliary system: the compressed air pressure needs to be stable at 0.4-0.6MPa (pressure fluctuation ≤± 0.02MPa), otherwise it will cause the glue volume to fluctuate between large and small; Heating devices (such as rubber hose heating belts) need to be started in advance to ensure a constant temperature of the rubber material during transportation (deviation ≤± 2 ℃).

運行過程中的實時監(jiān)控與調(diào)整是保證封膠質(zhì)量的核心。操作人員需持續(xù)觀察膠線外觀:正常膠線應(yīng)連續(xù)光滑、無氣泡、無缺膠,若出現(xiàn)氣泡(混入空氣),需停機排出膠管內(nèi)空氣;若膠線變細(膠量不足),檢查膠泵壓力是否下降(需維持在 0.8-1.5MPa);若出現(xiàn)毛邊(膠嘴磨損),及時更換膠嘴(更換時間<5 分鐘)。設(shè)備運行時需避免急停急啟(每日急停次數(shù)≤3 次),防止膠料在膠管內(nèi)積壓固化(固化后需拆解清理,耗時 2-4 小時)。對連續(xù)生產(chǎn)(>8 小時)的場景,每 2 小時需清潔膠嘴一次(用專用溶劑擦拭),防止膠料殘留堵塞;每 4 小時檢查一次膠料余量,余量<10% 時及時補膠(補膠時需避免混入空氣)。環(huán)境因素也需控制:車間溫度保持 15-30℃(低于 15℃時啟動環(huán)境加熱),相對濕度≤70%(高濕度會影響膠料固化速度),避免粉塵過多(需配備除塵裝置,粉塵濃度≤10mg/m)污染膠面。

Real time monitoring and adjustment during operation are the core to ensure the quality of sealing. The operator needs to continuously observe the appearance of the glue line: the normal glue line should be smooth, without bubbles, and without missing glue. If bubbles (mixed with air) appear, the machine should be stopped to discharge the air inside the hose; If the glue line becomes thinner (insufficient glue amount), check whether the pressure of the glue pump has decreased (it needs to be maintained at 0.8-1.5MPa); If there are burrs (worn rubber nozzle), replace the rubber nozzle in a timely manner (replacement time<5 minutes). During equipment operation, it is necessary to avoid emergency stops and starts (with a daily emergency stop frequency of ≤ 3 times) to prevent the rubber material from accumulating and solidifying in the hose (after solidification, it needs to be disassembled and cleaned, which takes 2-4 hours). For continuous production (>8 hours) scenarios, the rubber nozzle needs to be cleaned every 2 hours (wiped with a special solvent) to prevent residual rubber material from clogging; Check the remaining amount of adhesive every 4 hours, and promptly replenish the adhesive when the remaining amount is less than 10% (avoid mixing air when replenishing the adhesive). Environmental factors also need to be controlled: the workshop temperature should be maintained at 15-30 ℃ (environmental heating should be started when it is below 15 ℃), the relative humidity should be ≤ 70% (high humidity will affect the curing speed of the rubber material), and excessive dust (dust removal device should be equipped, dust concentration ≤ 10mg/m) should be avoided from contaminating the rubber surface.

設(shè)備維護與保養(yǎng)直接影響使用壽命和運行穩(wěn)定性。每日生產(chǎn)結(jié)束后,需徹底清洗膠路系統(tǒng):用清洗溶劑(如異丙醇、專用清洗劑)沖洗膠泵、膠管、膠嘴,直至流出液體無殘留膠料(清洗時間 10-15 分鐘),防止膠料固化堵塞(未清洗時故障率增加 50%)。每周檢查運動部件:導(dǎo)軌添加潤滑脂(每米導(dǎo)軌用量 5-10g),軸承檢查磨損(間隙>0.1mm 時更換),確保移動順暢(無卡頓)。每月校準(zhǔn)計量系統(tǒng):通過稱重法確認(rèn)實際膠量與設(shè)定值的偏差(偏差≤±3%),必要時調(diào)整膠泵轉(zhuǎn)速或壓力;檢查傳感器精度(如位置傳感器誤差≤0.1mm),確保定位準(zhǔn)確。長期停用(>7 天)時,需排空膠路內(nèi)所有膠料,注入保護劑(防止氧化腐蝕),并關(guān)閉電源和氣源,覆蓋防塵罩。

Equipment maintenance and upkeep directly affect the service life and operational stability. After daily production, the rubber system needs to be thoroughly cleaned: rinse the rubber pump, hose, and nozzle with cleaning solvents (such as isopropanol, specialized cleaning agents) until there is no residual rubber material flowing out (cleaning time 10-15 minutes), to prevent the rubber material from solidifying and blocking (failure rate increases by 50% when not cleaned). Weekly inspection of moving parts: add lubricating grease to the guide rail (5-10g per meter of guide rail), check for bearing wear (replace when clearance>0.1mm), ensure smooth movement (no jamming). Monthly calibration of the measuring system: Confirm the deviation between the actual glue amount and the set value through weighing method (deviation ≤± 3%), and adjust the glue pump speed or pressure if necessary; Check the accuracy of the sensor (such as position sensor error ≤ 0.1mm) to ensure accurate positioning. When it is not used for a long time (>7 days), all rubber materials in the rubber path should be emptied, protective agents should be injected (to prevent oxidation and corrosion), and the power and gas sources should be turned off, and a dust cover should be covered.

安全操作規(guī)范是避免事故的前提。設(shè)備運行時,操作人員需與運動部件保持安全距離(≥500mm),禁止用手接觸膠嘴或工件(防止夾傷或燙傷,膠料溫度可能達 50℃)。膠料和清洗劑多為易燃物,車間需禁止明火,并配備滅火器(每 50㎡至少 1 具);溶劑揮發(fā)氣體需通過排風(fēng)系統(tǒng)排出(風(fēng)量≥10 次 / 小時),濃度控制在爆炸下限的 25% 以下。設(shè)備接地電阻需≤4Ω(防止靜電火花),電氣系統(tǒng)需定期檢查絕緣(絕緣電阻≥1MΩ),避免漏電事故。此外,操作人員需經(jīng)培訓(xùn)合格后方可上崗,熟悉緊急停機按鈕位置(響應(yīng)時間<1 秒),確保突發(fā)情況時能快速停機。

Safe operating procedures are a prerequisite for avoiding accidents. During equipment operation, operators must maintain a safe distance (≥ 500mm) from moving parts and are prohibited from touching the rubber nozzle or workpiece with their hands (to prevent pinching or scalding, as the temperature of the rubber material may reach 50 ℃). Rubber and cleaning agents are mostly flammable materials, and open flames are prohibited in the workshop, and fire extinguishers (at least one per 50 square meters) should be equipped; The solvent volatile gas needs to be discharged through the exhaust system (air volume ≥ 10 times/hour), and the concentration should be controlled below 25% of the lower explosive limit. The grounding resistance of the equipment should be ≤ 4 Ω (to prevent static sparks), and the insulation of the electrical system should be regularly checked (insulation resistance ≥ 1M Ω) to avoid leakage accidents. In addition, operators must be trained and qualified before taking up their posts, familiar with the position of the emergency stop button (response time<1 second), and ensure that they can quickly stop the machine in case of emergencies.

本文由雙組份打膠機友情奉獻.更多有關(guān)的知識請點擊:http://www.ttkjhz.net我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.ttkjhz.net We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 全自動封膠線中中板壓與棍壓的區(qū)別 2025/11/15

- 中空玻璃加工設(shè)備?故障分析流程 2025/11/14

- 中空玻璃生產(chǎn)線:中空玻璃生產(chǎn)流程及所需要設(shè)備 2025/11/13

- 丁基膠涂布機液壓油的選擇指南 2025/10/31

- 玻璃涂布機設(shè)備操作流程 2025/10/30

- 雙組份打膠機比例怎么調(diào) 2025/10/29

- 全自動鋁條折彎機折彎角度偏差的解決方法 2025/10/29

- 中空玻璃丁基膠涂布機漏油怎么解決 2025/10/28

- 臥式丁基膠涂布機糾偏原理 2025/10/27

- 立式丁基膠涂布機故障維修 2025/10/25

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: